PLAINFIELD, Ind. — The 2025 football season is well underway, and some of the most popular helmets to keep players safe are manufactured in central Indiana.

"We are here at our Certor Sports Headquarters," said Zack Vesco, with Certor Sports, "which is our warehouse and manufacturing facility."

This is where two popular football helmet brands are born: Schutt and VICIS.

This year, dozens of Indianapolis Colts wear these helmets, including guys like Kenny Moore II, Michael Pittman Jr. and Daniel Jones.

"The guys really like the look and the comfort and the added protection with this helmet," Vesco said.

Inside the production facility, each helmet starts as tiny, polycarbonate pellets. They are melted down and injected into a mold. The process to create a helmet shell takes about one minute.

"Yeah, every minute or so, there is another shell that pops out," Vesco said, "and then, we get the rest of the process started."

Facemasks are pieced together by hand. Staff at Certor say those masks have been welded the same way for 75 years.

Once they are built, facemasks are then dipped in bubbling paint powder, coated and sent into an oven to harden. Within minutes, they are "ready for wear" on the other side.

The craftsmanship continues in the paint room. Hundreds of notable color swatches are turned into handcrafted paint buckets. Each helmet shell sits under watchful eyes and is tended to individually, taped by hand and painted.

Credit: WTHR

Credit: WTHROnce the structure of the helmet is assembled, filling the inside becomes the brains of the operation.

"The best testing helmet is a helmet that fits well," said Charlie Peterson, with Certor Sports.

Peterson and Vesco say Certor's Schutt F7 Pro is the fastest adopted helmet in the National Football League. It's an iconic look with modern technology.

Teams can use a tablet to create a 3D scan of a player's head to determine how to best customize and fit each helmet.

"If I click 'scan' here, where it becomes white, it slowly starts to pick up his head," Peterson said, as he demonstrated the technology. "I slowly scan his head."

The process takes about two minutes. Peterson says NFL and Division I partners can access the technology from their locker rooms.

"When they add a player in free agency or pick up somebody out of the draft, they can immediately take this tablet," Peterson said, "and then, they know exactly what size helmet they need. Then, we are able to build those custom there in the back and send them right out to the team."

The facility then makes a 3D lattice print for the lining of the helmet, complete with eight controllable pads and an on-board air system. Each helmet is customized for a specific player.

Vesco demonstrated the air system in the helmet.

"As I push this button in the back, it fills up with air here," Vesco said, "and then, we've got a release valve as well, all built into the helmet. So, on demand, players can inflate the back occipital of their helmet and tighten down their fit."

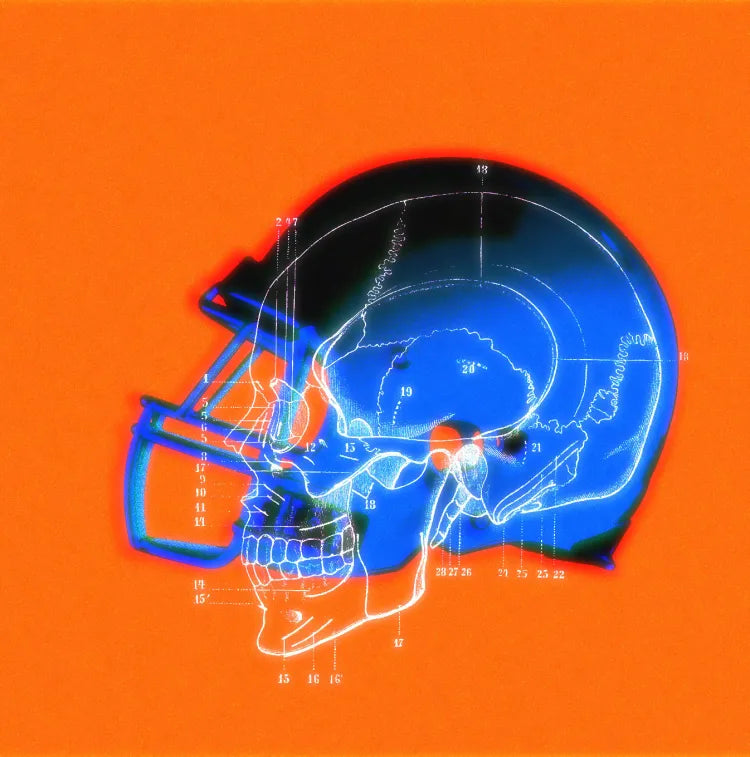

Each helmet undergoes several rounds of testing in the labs, including drop testing to replicate helmet-to-ground impact.

"VICIS was the first brand to roll out a quarterback helmet that performs better against helmet-to-ground impacts that quarterbacks experience," Vesco said.

Linear testing also replicates the unpredictability of on-field play.

"Being able to make sure that our helmets perform, regardless of where that collisions happens, is really important," Vesco said.

Certor produces helmets for athletes at all levels of competition, from the professionals to the peewees.

"Those guys are kind of bumping into each other rather than running over each other," Vesco said, "but being able to perform at a high level as well knows that we are going to be able to perform at that lower level of impact."

Vesco added, "Really understanding what your son is in is really important, and not just showing up and accepting what's available."

For Indiana athletes in Schutt and VICIS helmets, their protection and performance are homegrown in Plainfield, Indiana.

"It's the Crossroads of America," Vesco said. "It's really great to be here in Indiana and make this our home."