PLAINFIELD, Ind. — You might not know it, but some of the helmets you seen worn by players on Sunday, Saturday and Friday nights during football season are made in central Indiana.

”Across the NCAA and NFL, you’re talking 30%, upwards of 40%, of the helmets that they see are going to be made in this factory,” said Chad Hall, the Chief Marketing Officer for Certor Sports.

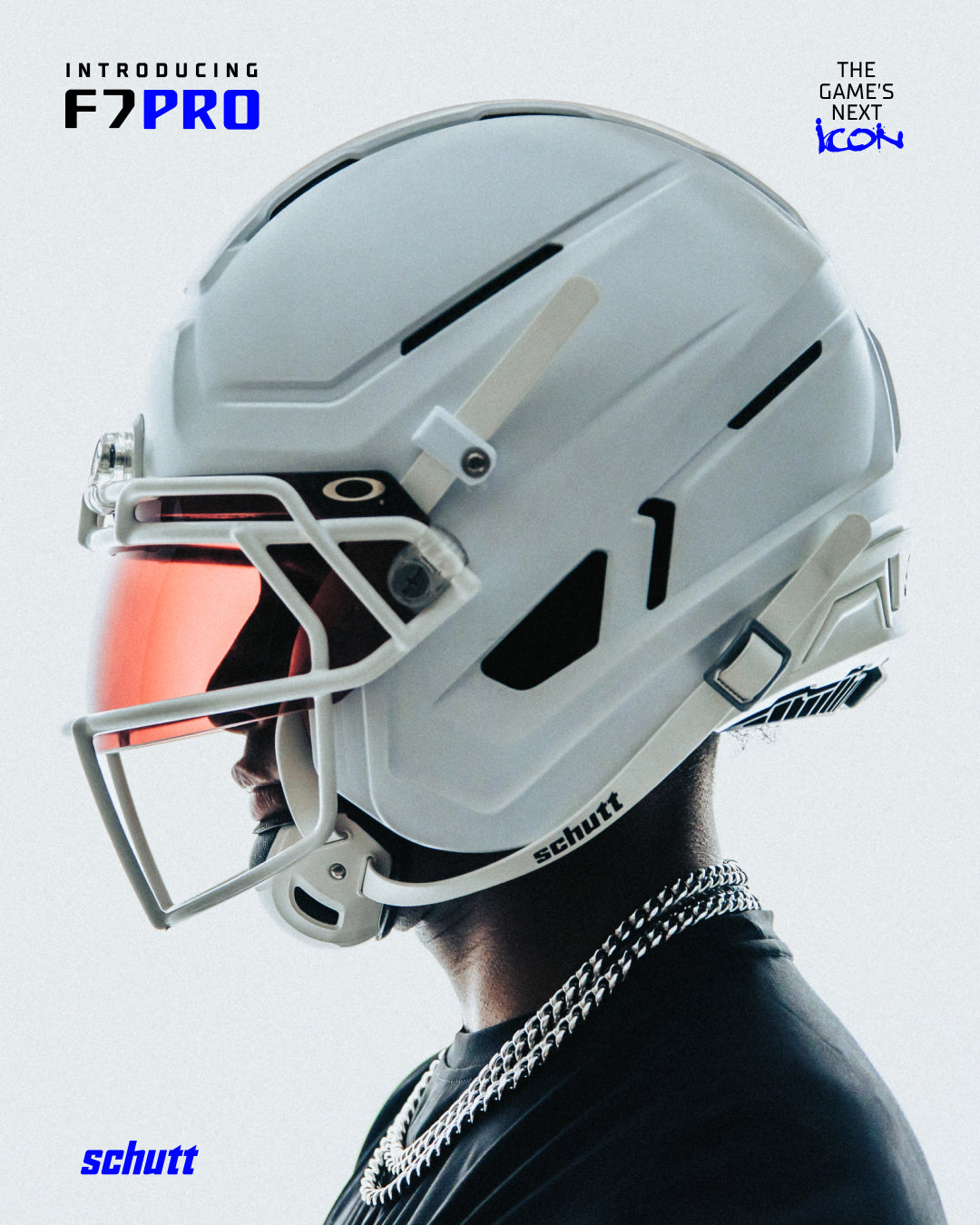

From its Plainfield factory, Certor Sports produces Schutt and VICIS helmets. These are two of the most popular helmet brands in football.

”Two models are in the top-five safest helmets in the game right now,” said Hall.

Each part of the helmet has a space inside the factory. A tour of the facility starts with the facemasks, where wire is bent and welded to make dozens of different types.

“Each little bend is unique and ultimately they get welded into a finished guard,” said Hall.

The beginning of the helmet is formed in an automated process that presses the material into a mold before a robotic arm drills the proper holes.

”You can see all of the holes that are being drilled, which are all for fastenings and different things like that,” Hall said. “It’s a very precise process.”

From there, the helmet is ready for one of 3,000 color options and decals depending on what team it might be going to.

”We do all of that masking before they go into the paint operation,” Hall said.

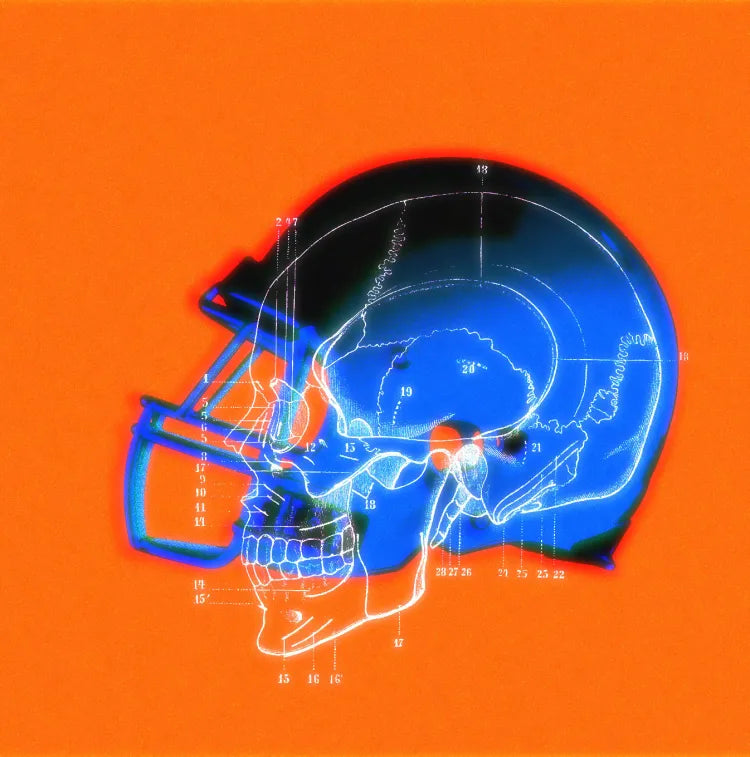

Finally comes the “brains,” or the interior of the helmet. The latest helmet from Certor, the Schutt F7 Pro, has padding on the interior that is softer in certain spots and firmer in others. It’s made to absorb the content and support the head.

This is a growing trend over the last several years, football helmets are being specially crafted for the player who is going to be wearing them.

”It’s fit, it’s function, it’s position,” Hall said. “Some of those things all go into the decision. Some players just want to wear the safest helmet, like they look at the list and they say, ‘I want to wear the safest one.’ Some want to wear the one they look the best in. Some are right in between. It depends on the player.”

When it comes to specifics on the position, different helmets can protect from the hits certain positions take most.

“Most quarterback impacts are going to be back of helmet to ground, so the helmets are specifically tuned to really protect for that capacity,” Hall said.

Often, the biggest players on the field – those roaming the trenches on the offensive or defensive lines – are taking the most hits. Hall said they’ve taken that into account with their VICIS ZERO2 TRENCH.

”It’s an attachment that goes on the front of the helmet,” Hall said. “So, for linemen who are taking those repeated blows, this is the number one ranked helmet on the NFL offensive and defensive line.”

These helmets take years to design, like their new Schutt F7 Pro, which will roll out onto the gridiron this fall.

”The structure of that is highly engineered and designed and it takes a long, long time to get it just right,” Hall said.

The safety in helmet technology is constantly evolving, meaning Certor is always chasing a safer helmet.

”We’re not just protecting Saturday and Sunday players at the elite level, we’re protecting high school players, we’re protecting youth players,” Hall said.

Full article and video: https://fox59.com/news/indynews/some-of-the-nfls-most-popular-helmets-are-made-in-plainfield/